Di {0}

Di {0}

OEM for well-known brands

OEM for well-known brands Supplier for Fortune 500 companies

Supplier for Fortune 500 companies Quality management certified

Quality management certified Years in industry(15)

Years in industry(15)

PLASTIC-INJECTION MOLDING

Plastic-injection molding is the preferred process for manufacturing plastic parts, as it is ideal for producing high volumes of low-cost plastic parts with high tolerance precision,repeatability and little to no finishing required.

In-house mold design and building capabilities, complete supply chain solutions.

Customers can choose from a vast selection of thermoplastics and thermosets that best suit their needs for strength and function.We’ve worked with many types of resins, including:

- Acetyl (POM)

- Acrylic (PMMA)

- Acrylonitrile-Butadine-Styrene (ABS)

- Nylon(PA)

- Nylon+Glass Fiber

- Noryl (PPO and PS)

- PC, PET, PE, PPS, PP, PS, PU, PBT, PEI, Peek and PTE

- Rigid and soft PVC

- Thermoplastic Elastomer (TPE)

- Thermoplastic Rubber(TPR)

- Styrene Acrylonitrile(SAN/AS)

- Polyether Sulphone(PES)

- Cellulose Acetate(CA)

Plastic finishes include:

- Metallization (chrome,gold,silver)

- Painting (hand,screen,automated)

- Vacuum plating

- Lithography

- Custom texturing

- Hydrographics

Rubber Injection Compression Molding

Rubber-molded parts are available through either the injection or compression molding processes. Rubber injection molding offers many of the same benefits as plastic-injected parts: low cost and high volume with minimal finishing. Compression molding, however, is particularly advantageous for large, fairly intricate parts.

Compression Molding is the original production method for molded rubber. It is a useful molding process for forming bulky parts, bellows, grommets, gaskets, seals and O-rings, etc. It is a widely used, efficient, economical production method for many products particularly low production volumes of medium to large parts, materials with a high cost and applications that demand extreme hardness. The process involves compressing preformed rubber in a mold with a press. During the compression process, rubber is forced into the mold cavity to form the final product.

Advantages

Rubber Compression Molding offers advantages over other methods by providing:

- Tooling savings

- Short setup time (saves on short production runs)

- The capacity to process stiff,high durometer materials

- Least amount of waste

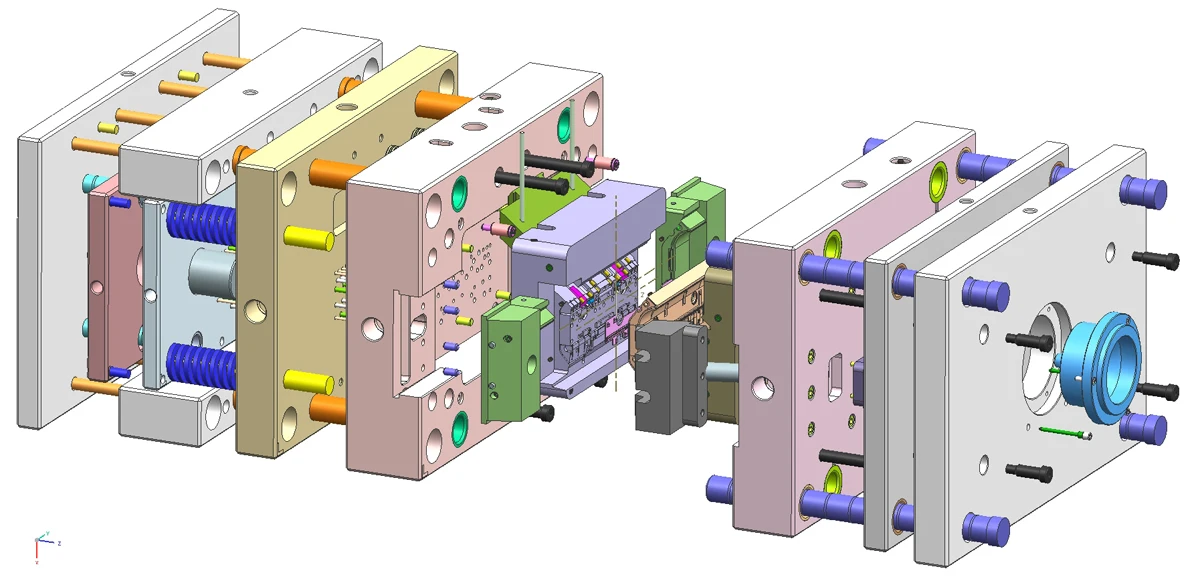

MOULD

Mould is a fundamental technological device for industrial production. Industrially produced goods are formed in molds which are designed and built especially for them. The mould is the core part of manufacturing process because its cavity gives its shape. There are many kinds of mould, such as injection moulds, extruding moulds, compression moulds, die-casting moulds, glass moulds, ect.

NEWAY is with In-house mold design and building capabilities for various mould making for rubber and plastic items. Hot runner system and cold runner system offered. We are very professional, and offer very high precision moulds.

PROTOTYPING

A prototype is an early sample, model,or release of a product built to test a concept or process or to act as a thing to be replicated or learned from. A prototype is designed to test and try a new design to enhance precision by system analysts and users. Prototyping serves to provide specifications for a real, working system rather than a theoretical one. In some work flow models, creating a prototype (a process sometimes called materialization) is the step between the formalization and the evaluation of an idea.

Advantages & Disadvantages

In general, it can be expected that individual prototype costs will be substantially greater than the final production costs due to inefficiencies in materials and processes. Prototypes are also used to revise the design for the purposes of reducing costs through optimization and refinement.

It is possible to use prototype testing to reduce the risk that a design may not perform as intended, however prototypes generally cannot eliminate all risk. There are pragmatic and practical limitations to the ability of a prototype to match the intended final performance of the product and some allowances and engineering judgementsare often required before moving forward with a production design.

Building the full design is often expensive and can be time-consuming, especially when repeated several times—building the full design, figuring out what the problems are and how to solve them, then building another full design. As an alternative, rapid prototyping or rapid application development techniques are used for the initial prototypes, which implement part, but not all, of the complete design. This allows designers and manufacturers to rapidly and inexpensively test the parts of the design that are most likely to have problems, solve those problems, and then build the full design.

Material: ABS, POM, PP, PC, PE, PA(Nylon), PVC, PBT, etc.

Main Process: SLA, SLS, CNC, PJP

| Stereolithography (SLA) |

A rapid prototyping process that uses a vat of liquid UV-curable photopolymer resin and a UV laser to build parts one layer at a time. SLA rapid prototyping is a great process for concept models, master patterns and trade show models. |

| Selective Laser Sintering (SLS) |

A rapid prototyping process that uses a high power laser to fuse small particles of powder to build parts one layer at a time. SLS rapid prototyping is a great process for functional testing and for low volume manufacturing. |

| Plastic Jet Printing(PJP) | A rapid prototyping process that uses a plastic filament of material supplied to an extrusion nozzle. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions, PJP rapid prototyping is a great process for functional testing and for low volume manufacturing. |

| Quick Plastic Cast Urethane |

The process of using silicone molds to create urethane molded parts. Silicone is cast around a master pattern(typically made from stereolithography rapid prototyping). After curing, the mold is then used to form a two-part polyurethane material in the shape of the master. Cast Urethane Molding is a great process for Pre-production runs and low volume manufacturing. |

| Computer Numerical Control(CNC) |

CNC Machining is a subtractive manufacturing method which cuts away unwanted material from primary stock to form the shape of the needed parts. It is a great process for manufacturing low and high quantities of quality metal and plastic parts. |

|

Quick Sheet Metal |

A formative manufacturing process that produces parts from sheets of metal. A variety of processes are available including stamping, bending, drilling, tapping, shearing and more. |